Nick Banks - Design Portfolio

Technical and creative designer with over ten years professional experience of 2D and 3D CAD and CAM. Working recently in the design of hands-on interactive exhibits for science education backed up with experience of precision technical design and manufacture in the motorsport industry and mass production in vacuum cleaner design. Experience of all aspects of a products life cycle from concept generation, through design and development and into evaluation and production.

Exhibits and Exhibitions

W19 DESIGN (Bristol, UK) 2010 to present – Director/Designer

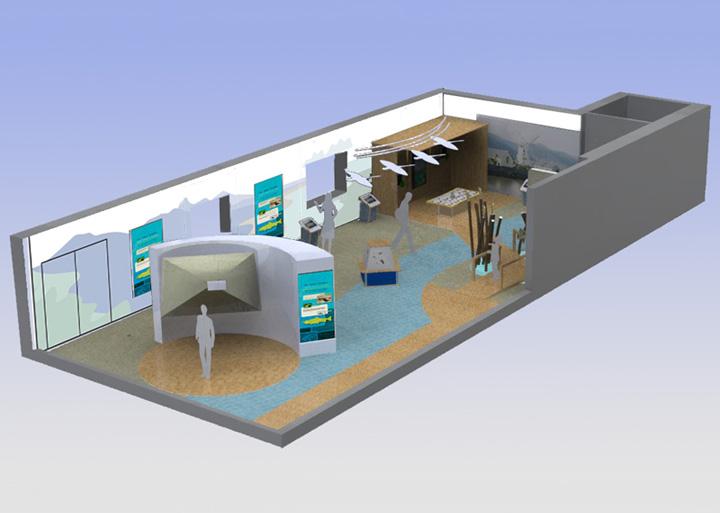

After working as part of a larger organisation I have now set up my own company for the design and construction of exhibitions, exhibits and interactive elements for science centres, museums and visitor centres. My goal is to offer high quality, bespoke interactive exhibits at a much more affordable cost by having vastly reduced overheads. I aim to bring engineering and product design to exhibit design and production.

I have designed a built exhibts for exhibitions from the UK and Ireland to Kazakhstan amongst others. I use state of the art 3D CAD to design and develop exhibits then use in house or external fabrication to produce a robust, high-quality engaging product

EXPLORE AT-BRISTOL (Bristol, UK) 2006 to 2010 – Senior Design Engineer

Explore at-Bristol is one of the UK’s leading science and discovery centres. I managed a small team of designers who design, develop and build new interactive exhibits. Designs were created using Solidworks then production engineered for in-house fabrication, including 3D CNC, or out-sourced. Personal responsibilities included managing budgets and time-plans, writing risk assessments, health and safety training, coordination of design activities and reporting to the board. I streamlined CAD based design development giving clear direction to the design team by using templates, macros, the creation of a best practice guide and developed new construction documentation. I also introduced and managed new standards for test specifications and electrical and mechanical safety for each product.

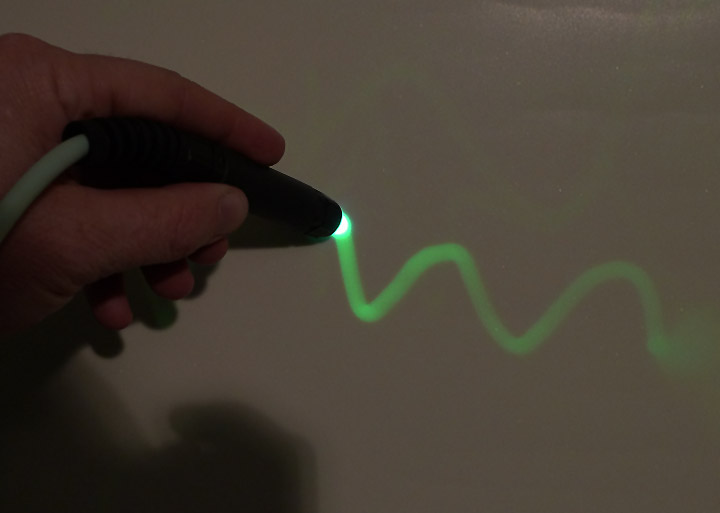

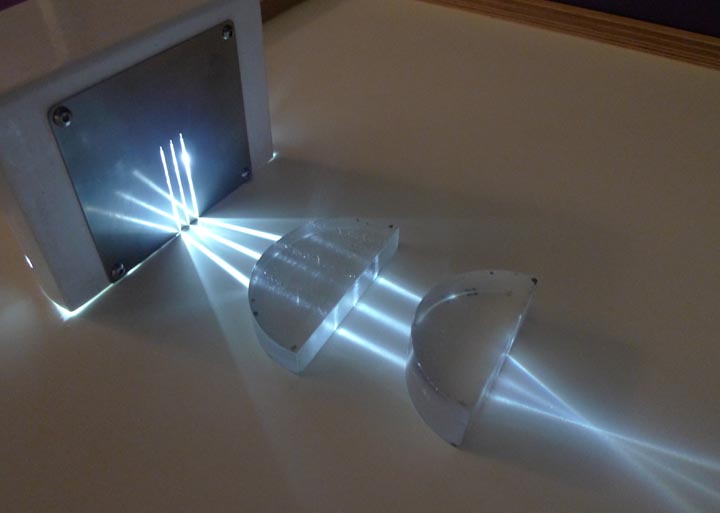

I have developed a wide range of interactives including a set of 36 tabletop exhibits to take the science centre experience to schools and community groups; a travelling exhibition themed around DNA using IT and physical interaction; a small set of exhibits themed around flight in conjunction with Airbus and Rolls Royce and a ‘hands-on’ Aardman animation exhibition. Overall I was responsible for the design, testing, production and installation of over 200 exhibits.

Live Lab - At-Bristol. A real lab in the heart of the exhibition

Aardman Animation exhibition - control lighting on a real Aardman set

Animators studio. Hands on animation interactive exhibition

At Bristol flight gallery exhibition

'Launch it' interactive exhibit. Winch your objects to the roof then watch them fall

Travelling exhibitions

TECHNIQUEST (Cardiff, UK) 2004 to 2006 - Design Manager

Techniquest is another leading science and discovery centre. My role involved managing a small, multidisciplinary design team developing new exhibits for the exhibition floor in Cardiff as well as other science centres around the world. Designs were created using Cobolt and later NX3. Major pieces of work have included: The design of a travelling genetics exhibition for Wales Gene Park; Design of 15 new interactive exhibits for a music based exhibition; Re-design of a range of proven exhibits to significantly reduce time to re-manufacture. All of these projects have required a thorough understanding of the technical and educational content as well as managing manufacture within the company and outsourcing of components where appropriate.

Motorsport Transmissions

XTRAC TRANSMISSION TECHNOLOGY (Thatcham, UK) 2001 to 2003 - Design Engineer

I was part of the design team at Xtrac who are one of the world leaders in motorsport transmissions. I worked on the design of a number of gearbox components in a range of exotic metal alloys. Designs were created using 3D CAD then detailed, high-precision drawings and engineering models were produced for in-house manufacture working closing with a team of CNC operators working to very tight tolerances. Customers demanded strict change control and documentation. Reference library images shown below due to confidentiality.

Product Design

DYSON RESEARCH LTD (Malmesbury, Wilts, UK) 1997 to 2000 - Senior Design Engineer

During my time a Dyson I was responsible for steering and approving the design work of junior members of the team including signing off drawings for new parts and mould tools. Working on the Dyson robotic vacuum cleaner I was involved in bringing together many areas of work that were new to Dyson such as working with software, PCBs and sensors as well as traditional plastic parts. I managed a multi-disciplinary team and worked closely with testing and production departments. The work involved writing specifications, chairing meetings, managing budgets and personal development for team members as well as keeping company chairman, James Dyson, up to date with progress. I took the Dyson robotic vacuum cleaner from prototype to production readiness; set up a ‘Good Practices’ guide to standardise best working practices across the company; re-designed a range of ‘end of line’ tests for a production vacuum cleaners; developed a high-speed air flow smoothing and silencing system.

Skills

Compter Aided Design (CAD)

- Full parametric modelling, CAM, drawings, assemblies, BOMs, FEA, macros, fly-throughs

- Solidworks – advanced user and system manager

- NX (and Unigraphics) – advanced user

- AutoCAD, Cobolt, and EdgeCAM - experienced user

Manufacture

- Programming and operating a range of AXYZ-Pacer 3 axis CNC routers

- Good workshop skills including milling, lathe work, welding and hand tools.

- Mould tool prototyping and design

- Microelectronic and analogue electrical circuit design, construction and testing

- BS308 and BS8888 Drawing Standards and 2006/42/EC Machinery Directive